ABSTRACT

This experiment uses an electromagnetic shaker to produce standing wave patterns on the surface of a vertically oscillating sample of silicon liquid. These surface waves, known as Faraday waves, form shapes such as squares, lines, and hexagons. They are known to be dependent upon the frequency and amplitude of the forcing as well as on the viscosity and depth of the liquid in the dish. At a depth of 4mm and for various silicon liquids having kinematic viscosities of 10, 20, and 38 cSt, we determined the acceleration at which patterns form for frequencies between 10 and 60 Hz.

For the 10 and 20 cSt cases, it was found that the acceleration at which these patterns form does not heavily depend upon the viscosity of their host liquid. This is in stark contrast with the current body of knowledge. The case for 38 cSt, however, varies from the other two cases in both value and shape.

EXPERIMENTAL DESIGN

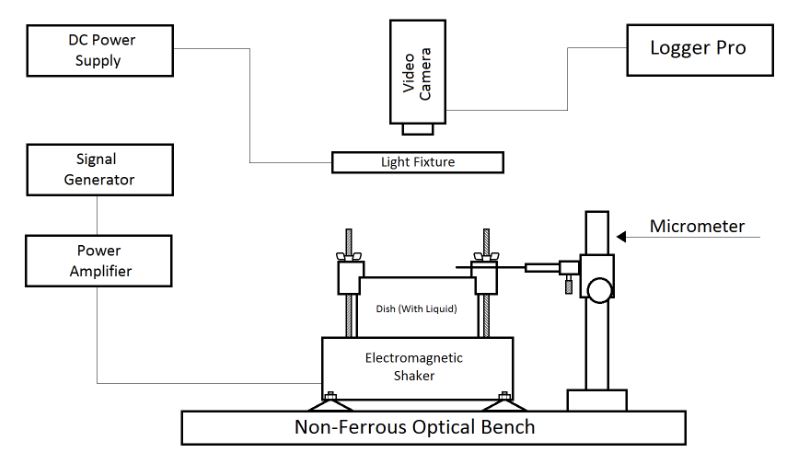

Figure 5 . Diagram of experimental apparatus used to obtain data

A block diagram of the experimental apparatus used in this experiment is shown in Figure 5. An ED-3 Electrodynamic Shaker was used to vertically oscillate a dish containing silicon oil of known viscosity at a depth of 4mm. It operates by using an electrified coil to move a magnet at a frequency and amplitude specified by the user through the Agilent 33220A Signal Generator. Proper operation of the shaker requires that a load of 2-5 pounds be applied.

IMPROVEMENTS

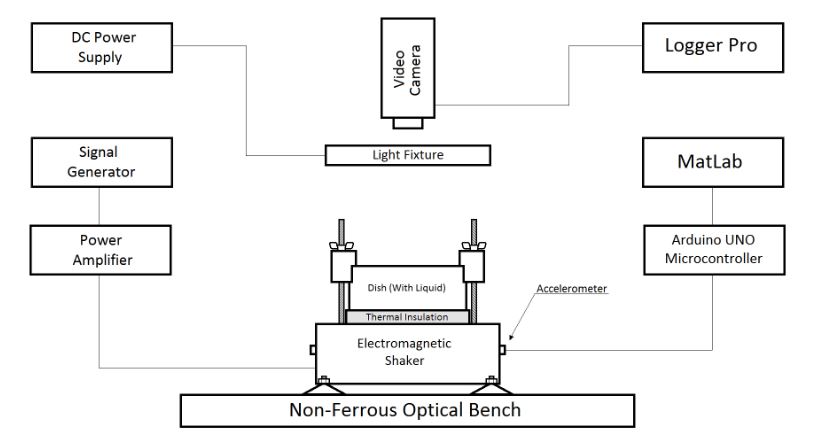

Figure 6 . Experimental apparatus, with improvements. Thermal insulation was added between the shaker and sample as well as the accelerometers and their associated data acquisition system

After collecting the data presented herein, some improvements were made upon the apparatus in an attempt to remedy certain issues. These are shown in Figure 6. Unfortunately, there was not time enough to obtain new data utilizing said improvements. During experimentation, inconsistent amplitude measurements were observed and the accuracy of our methodology for obtaining these measurements fell under scrutiny. In an attempt to remedy these inconsistencies, a more detailed method was adopted.

RESULTS

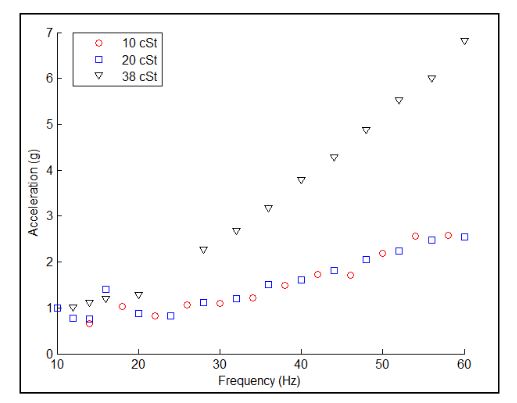

Figure 7. Pattern formation thresholds for 10, 20, and 38 cSt as a function of forcing frequency and acceleration. Note that the thresholds of 10 and 20 cSt are similar

The acceleration was then converted to be represented in terms of earth’s gravitational acceleration, g. For each of the three viscosities, these threshold values can be seen in Figure 7 as a function of frequency and acceleration. Interestingly, there appears to be no significant dependence of pattern formation threshold upon the viscosity of the liquid for 10 and 20 cSt viscosities.

CONCLUSIONS

In this experiment, silicon liquids having kinematic viscosities of 10, 20, and 38 cSt were oscillated in the vertical direction. It was found that the plots of threshold accelerations for the 10 and 20 cSt liquids were similar in shape and value, whereas the plot for the 38 cSt liquid differed in both ways. The result for 10 and 20 cSt viscosities opposes the findings of Kudrolli and Gollub by suggesting that, in some cases at least, the formation thresh old does not depend upon viscosity.

Further investigation of this system is expected, mainly to study the case for liquid having a 5 cSt viscosity. It was also found that the relationship between peak separation and frequency is inversely linear. This was expected due to previous qualitative observation. In the future, we expect to investigate the phenomenon of stochastic resonance, where noise added to the signal affects formation thresholds. It is expected that the addition of purely random, non-periodic noise would lower the amplitude of formation.

Additional future plans involve applying a complex waveform to the shaker, specifically the superposition of two sine waves with systematically applied differences in phase, wavelength, and amplitude. Other studies have shown that this regime provides for a richer variety of patterns than were found herein. Once this system is sufficiently well-understood, the test sample will graduate to something granular, such as sand, cornstarch, or steel shot.

Source: California Polytechnic State University

Author: Lisa Michelle Slaughter