ABSTRACT

Fatal accidents associated with underground coal mines require the implementation of high-level gas monitoring and miner’s localization approaches to promote underground safety and health. This study introduces a real-time monitoring, event-reporting and early-warning platform, based on cluster analysis for outlier detection, spatiotemporal statistical analysis, and an RSS range-based weighted centroid localization algorithm for improving safety management and preventing accidents in underground coal mines. The proposed platform seamlessly integrates monitoring, analyzing, and localization approaches using the Internet of Things (IoT), cloud computing, a real-time operational database, application gateways, and application program interfaces.

The prototype has been validated and verified at the operating underground Hassan Kishore coal mine. Sensors for air quality parameters including temperature, humidity, CH4, CO2, and CO demonstrated an excellent performance, with regression constants always greater than 0.97 for each parameter when compared to their commercial equivalent. This framework enables real-time monitoring, identification of abnormal events (>90%), and verification of a miner’s localization (with <1.8 m of error) in the harsh environment of underground mines. The main contribution of this study is the development of an open source, customizable, and cost-effective platform for effectively promoting underground coal mine safety. This system is helpful for solving the problems of accessibility, serviceability, interoperability, and flexibility associated with safety in coal mines.

RELATED WORK

Initially, the concept of digital underground mines was introduced with a very narrow vision of limited communication and the involvement of an operator. Now, this concept can be divided into separable categories of wireless communication and expert systems for safety and rescue in underground mines, personal position monitoring, and database systems. A wide range of literature on the present wireless communication and environmental monitoring in underground coal mines is summarized. WSNs use in underground mines is a new area of research. Recently, a highly robust smart system was implemented at Shangwan Coal Mine, Erdos, China. They upgraded a previously developed cable environmental monitoring system to a WSN.

SYSTEM OVERVIEW

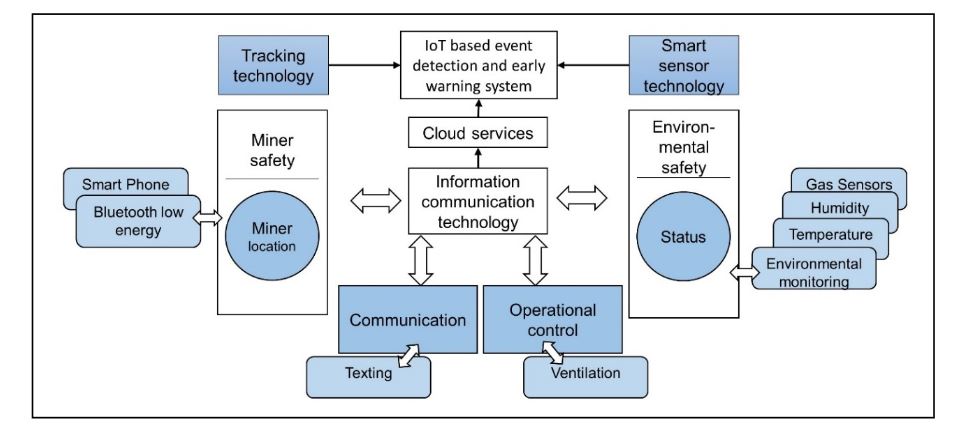

Figure 1. Internet of Things (IoT)-based integration of technologies for early-warning safety of underground coal mines

The cloud is helpful for determining the service state of mine and for sharing information. Thus, seamless integration can result in a reduction in mine accidents. In short, a lack of closely-coupled information sharing between “things”, miners, and mine management make it difficult to generate a quick response to emergencies occurring in underground mines. Therefore, integration based on the IoT concept is necessary for effective data collection, data analysis, automatically detecting abnormal events, and information sharing. Figure 1 shows the integration of different technologies used in early warning integrated system using IoT for underground coal mines.

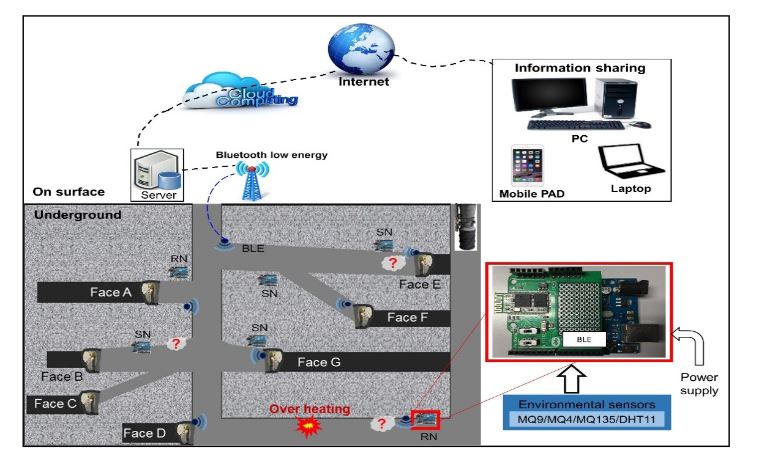

Figure 3. The overall architecture of the proposed IoT system for underground

The architecture of IoT-based event detection and early-warning systems for underground coal mines is shown in Figure 3. The Arduino-based sensor network utilizes the Bluetooth communication protocol to cover the entire mine. In this network, the nodes are divided depending upon their function. Stationary nodes (SN) are the basic nodes for monitoring mine air parameters, and router nodes (RNs) are the parental nodes with a subordinate cluster consisting of a few SNs. Finally, both SNs and RNs transmit data to the base station (BS) through a gateway using a Bluetooth communication protocol.

SYSTEM DESIGN

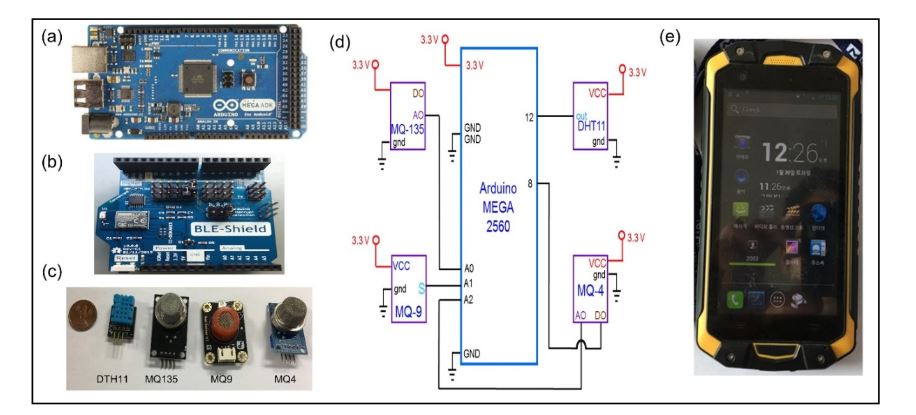

Figure 4. (a) Arduino MEGA 2560; (b) BLE shield for Arduino; (c) photos of sensors; (d) circuit diagram of sensors attachment to Arduino MEGA 2560; (e) mobile node carried by the miners

The basic sensing unit of the proposed IoT platform is Arduino, a microcontroller for digital and analog input/output (I/O). The Arduino MEGA 2560 microcontroller (ATmega1280, Atmel, San Jose, CA, USA) (Figure 4a) with MQ-9, MQ-4, MQ135 and DTH11 (D-Robotics, London, UK) (Figure 4c) sensor modules were used for monitoring the underground environment. Figure 4d shows the circuit diagram of sensors attached to the different pins of the Arduino MGEA. Arduino MEGA is an open-source microcontroller chip for reading and writing OUTPUT data in real-time. Arduino was used because of its fast and easy prototyping, low-cost, support of existing libraries, and the fact that it is used by a large community as a common hardware for IoT.

METHODS AND MODELS

Real-time continuous gas monitoring for ambient intelligence and outlier detection, and miner tracking are basic features of this study. The determination of the state of the mine as a single index is a unique feature of our proposed IoT system. We introduce a “Mine Warning Index (MWI)” for an easy and quick assessment of the state of the mine as normal, warning, and alarming. This index is based on the threshold limit values of gas concentrations. Moreover, ambient intelligence is also introduced in this system based on temporal statistical models.

IMPLEMENTATION: CASE STUDY

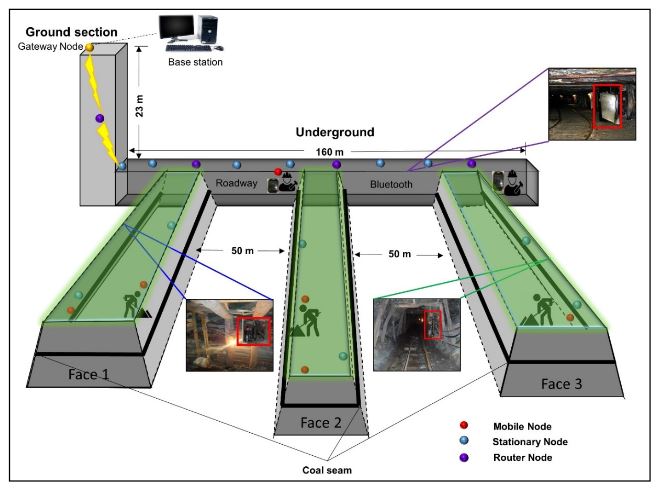

Figure 6. Layout of SNs, RNs, gateway and moving anchor (MN) in the Hassan Kishore coal mine for enhanced safety

The average distance between BLE nodes was approximately 17–18 m, and this was selected by considering the mine opening surface conditions, as uneven surfaces greatly influence the WSN range. The chosen distance allows for the overlapping of a single node with at least three consecutive nodes. Thus, in the case that one or two nodes fail, our system can reconfigure itself with a node within range. This gives a high density of locations of each of SNs and RNs inside the mine. These are summarized in Table 7 and shown in Figure 6. The position of MN is also shown in Figure 6 as a red color, the SNs are represented as a blue color, while RNs are shown as an indigo color.

SYSTEM PERFORMANCE AND EVALUATION

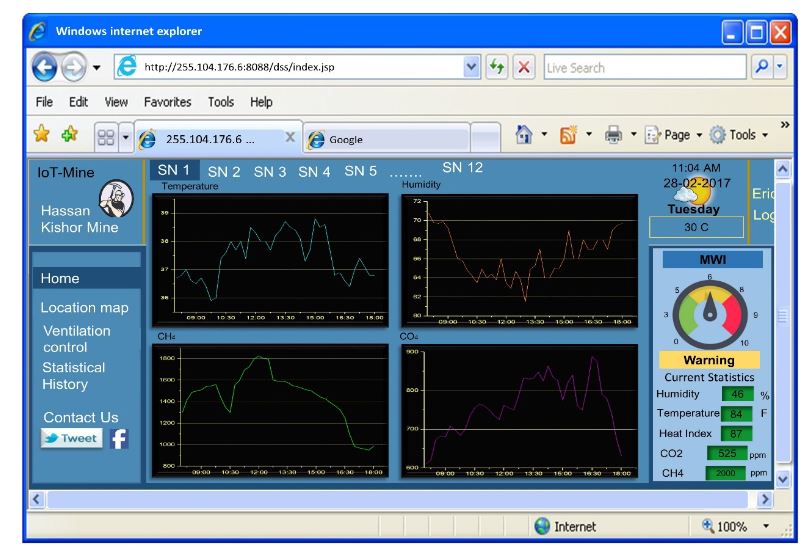

Figure 10. Screen shot of sensing data and information sharing based on IoT

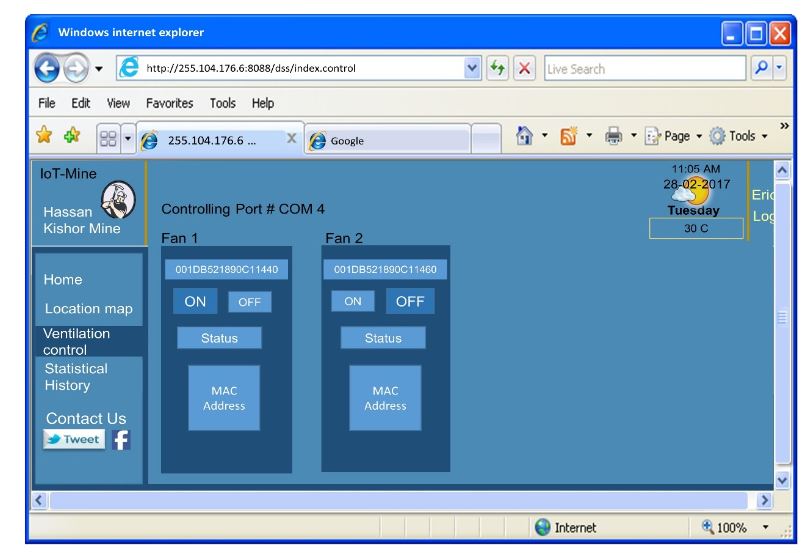

Figure 11. Screen shot of the designed computer interface for ON/OFF switching of auxiliary fans

In this system, Java 2 Enterprise Edition (J2EE), support application platforms, e-Science platforms, and Web 2.0 applications were utilized for the system interface (described in Section 4.3). Moreover, java data base connectivity (JDBC) was used for the I/O data. Figure 10 shows a screen shot of standard monitoring at different SNs. Figure 11 shows how the Web interface switches to turn ON/OFF two actuators of ventilation fans remotely via a computer. The main server easily detects environmental conditions by comparing present readings with threshold limits values for the initial assessment of the serving state of the mine. The warning is in the form of emergency lights and alarms; therefore, some of the nodes were equipped with alarms and warning lights.

DISCUSSION

Before the implementation of this system, there was no safety management system in the mine except for the simple telephone communications between the surface and underground stations. The previous method of manual entries of accidents were not reliable and made it extremely difficult to build a quantitative comparison between the number of accidents before and after the installation of the integrated system.

Therefore, four persons (mine manager, a technical consultant, and two miners from the mine staff) were interviewed after the implementation of this system. After the implementation of this system, a training session was arranged for miner’s training and explaining to them the benefits of this system. Afterwards, the two representatives of miners were interviewed. They showed the positive response for carrying MN, because of its light weightiness, safety concerns, and also as a source of entertainment. Also, there was a significant reduction in mine accidents.

CONCLUSIONS

In this paper, we introduced an initial effort towards an IoT-based early warning, event detection, and information sharing integrated platform that has the potential to provide comprehensive safety and improved services in underground coal mines. Our system integrates underground mine environment monitoring, miner location tracking, and cloud services through the application program interfaces for data analytics. This system has been successfully implemented at the Hassan Kishore coal mine, an operating underground coal mine.

Arduino sensor modules were selected to measure five parameters i.e., temperature, humidity, CO2, CO, and CH4 at different locations in the underground mine with more than 95% and greater than 99% of accuracy and efficiency, respectively. The results obtained from the system implementation clearly indicated the status of the mine in terms of a “Mine Warning Index (MWI)”. The contingency table of MWI is based on the threshold limit values of gases, temperature, and humidity. Implementation in actual conditions confirmed some of the claims in a recent literature survey that covered toxic gases, seamless integration, and event detection, namely that a simple temporal statistical based ambient intelligence approach is far better than conventional qualitative decision-making.

K-means clustering with Euclidean distance measurements and silhouette values are efficient in detecting abnormal events in an underground coal mine environment. Attributed and spatio-temporal correlated event detection algorithms provide early warnings to prevent disasters by analyzing sensor data. The RSS range-based centroid algorithm is efficient for tracking miners, but the accuracy is low. A web-based lightweight remote monitoring and control system with a REST style is efficient and consumes less memory when providing access to underground sensors.

Source: Hanyang University

Authors: Byung Wan Jo | Rana Muhammad Asad Khan

>> 200+ IoT Led Projects for Final Year Students

>> More Wireless Projects using Arduino for Final Year Students

>> More Wireless Bluetooth Projects for Final Year Students

>> More Wireless Projects Using Microcontroller for Engineering Students