ABSTRACT

We present a new methodology to create colorful textile antennas that can be embroidered within logos or other a esthetic shapes. Conductive threads (e-threads) have already been used in former embroidery unicolor approaches as attributed to the corresponding conductive material, viz. silver or copper. But so far, they have not been adapted to ‘print’ colorful textile antennas. For the first time, we propose an approach to create colorful electronic textile shapes. In brief, the embroidery process uses an e-thread in the bobbin case of the sewing machine to embroider the antenna on the back side of the garment.

Concurrently, a colorful assistant yarn is threaded through the embroidery needle of the embroidery machine and used to secure or ‘couch’ the e-threads onto the fabric. In doing so, a colorful shape is generated on the front side of the garment. The proposed antennas can be unobtrusively integrated into clothing or other accessories for a wide range of applications (e.g., wireless communications, Radio Frequency Identification, sensing).

EMBROIDERY PROCESS FOR COLORFUL TEXTILE ANTENNAS

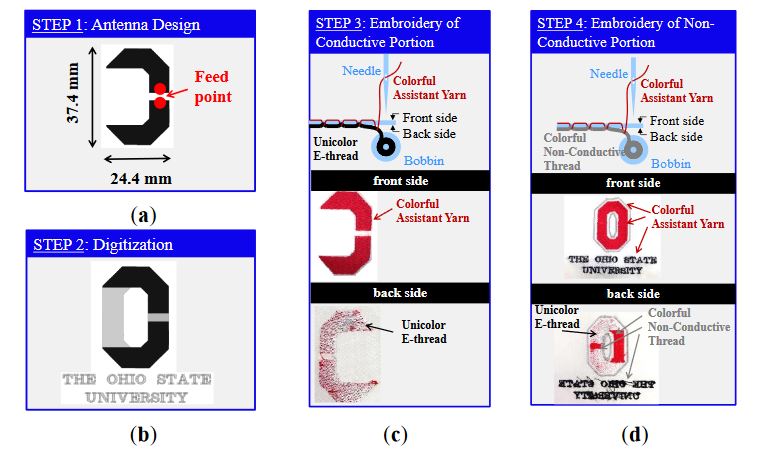

Figure 2. Proposed technology for colorful logo antennas: (a) STEP 1: antenna design

In brief, the embroidery process uses an e-thread in the bobbin case of the embroidery machine to ‘print’ the antenna on the back side of the garment. Concurrently, a colorful assistant yarn is threaded through the needle of the embroidery machine and used to secure or ‘couch’ the e-threads onto the fabric. In doing so, a colorful shape is generated on the front side of the garment. This embroidery process is depicted in Figure 2, and can be summarized as follows.

VALIDATION OF A COLORFUL TEXTILE DIPOLE ANTENNA AS PART OF THE OSU LOGO

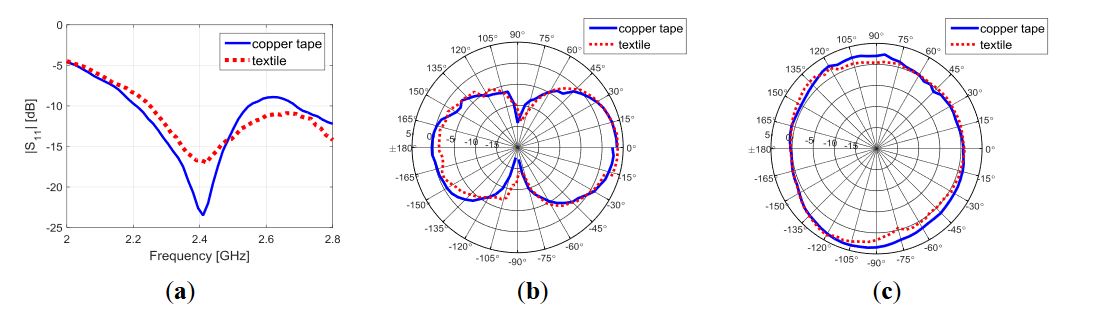

Figure 4. Measured performance of the textile and copper tape dipole prototypes

The measured reflection coefficient, |S11|, of the textile and copper antennas is given in Figure 4a, indicating good agreement. The corresponding measured realized antenna gain patterns at 2.4 GHz are shown in Figure 4b (E-plane) and Figure 4c (H-plane). As seen, excellent agreement is achieved. We may conclude that the colorful textile antenna prototype achieves excellent performance as compared to its copper counterpart.

CONCLUSIONS

A new embroidered approach was presented to realize colorful textile antennas that can form part of embroidered logos or other a esthetic shapes. The resulting textile antennas are flexible, lightweight, and mechanically robust to withstand daily wear and repetitive washing/drying. Such prototypes can be unobtrusively embroidered onto all sorts of clothing and accessories for a very wide range of applications (e.g., wireless communications, RFIDs, sensing).

To validate our technology, we fabricated and tested a 2.4 GHz colorful textile dipole antenna, integrated as part of an embroidered OSU logo. Reflection coefficient, gain, and pattern data indicate excellent agreement between the textile prototype and its copper counterpart. Future work will involve: (a) radiation efficiency measurements, (b) performance evaluation of colorful textile antennas placed upon the human body, and (c) performance evaluation of colorful textile antennas after washing and stressing.

Source: The Ohio State University

Authors: Asimina Kiourti | John L. Volakis

>> 60+ Antenna Communication Projects for Engineering Students

>> Project Report on Microstrip Patch Antenna for Engineering Students