ABSTRACT

This work proposes the development of an embedded real-time fruit detection system for future automatic fruit harvesting. The proposed embedded system is based on an ARM Cortex-M4 (STM32F407VGT6) processor and an Omnivision OV7670 color camera. The future goal of this embedded visit on system will be to control a robotized arm to automatically select and pick some fruit directly from the tree.

The complete embedded system has been designed to be placed directly in the gripper tool of the future robotized harvesting arm. The embedded system will be able to perform real-time fruit detection and tracking by using a three-dimensional look-up-table (LUT) defined in the RGB color space and optimized for fruit picking.

Additionally, two different methodologies for creating optimized 3D LUTs based on existing linear color models and fruit histograms were implemented in this work and compared for the case of red peaches. The resulting system is able to acquire general and zoomed orchard images and to update the relative tracking information of a red peach in the tree ten times per second.

BACKGROUND

Recent advances in computers and the improvement in micro-fabrication technology have fostered the design of tiny embedded systems with onboard electronics and sensors that also incorporates image-processing capabilities. For example, a versatile low cost embedded vision platform was presented to find blobs of a specific color in an image and also perform JPEG compression, frame differentiation, edge detection, image convolution, face detection, and color histogram computation.

EMBEDDED VISION SYSTEM

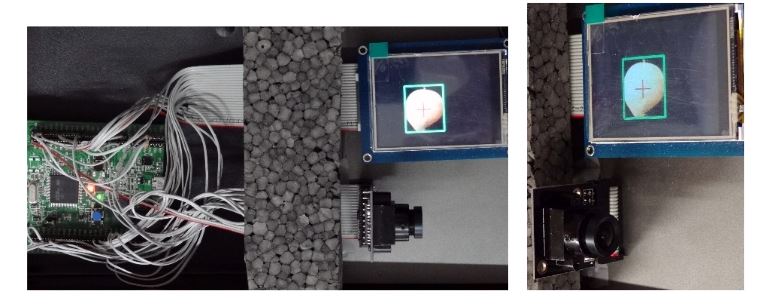

Figure 1. The camera module, the board processor and the auxiliary color LCD

Figure 1 shows the complete embedded system containing the processor module, the camera, and an auxiliary color LCD that can be plugged in to obtain fast feedback from the embedded system. The communication between the embedded system and other external computers is performed by defining a standard client USB Communication Device Class (CDC). This is a generic client USB class that is identified by other computers as a new virtual serial port operated as a standard RS232 communications port.

Figure 3. The processor used in the embedded system

The processor board, based on the STM32F407VGT6 (see Figure 3) processor can operate internally as a digital signal processor (DSP) and has a single-precision floating-point unit (FPU) allowing operations entirely done by hardware in a single cycle for most of the instructions. The microcontroller was configured to use an external crystal oscillator of only 8 MHz (see Figure 3) that is internally converted into an operative frequency of 168 MHz to operate at up to 210 Dhrystone MIPS.

CREATION OF A 3D LOOK-UP TABLE FOR RED PEACH DETECTION

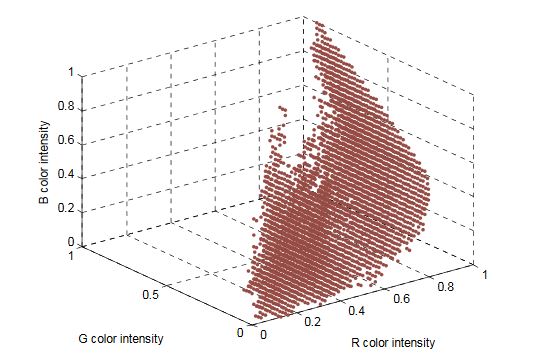

Figure 5. Red peach segmentation LUT obtained from a three-dimensional histogram

The resulting 3D LUT will summarize all object color knowledge described previously with the three-dimensional histogram. Figure 5 shows the red peach segmentation LUT obtained from the three-dimensional histogram created by selecting the area corresponding to red peaches in different images of an orchard. This LUT was created with 32 levels in the R index color vector, 62 in the G index color vector, and 32 in the B index color vector to directly segment the RGB565 images acquired by the onboard camera of the embedded system.

EXPERIMENTAL RESULTS

Figure 6. Orchard image (320 × 240 pixels, RGB565) obtained in normal

In the normal mode (Figure 6(a)) the camera is requested to submit 320 × 240-pixel default images and it offers this image just by sampling (by a factor of 2) the rows and colors of a base 640 × 480 RGB image. This mode offers an image that covers the full angle of view of the lens available on the camera. In the zoom mode (Figure 6(b)), the starting and ending rows and columns of the resulting image can be configured to generate an effective sequential window of 320 × 240 pixels with a narrow angle of view that can be displaced along the original 640 × 480 image matrix of the image.

CONCLUSIONS

This work proposes the development of an embedded real-time fruit detection system ready to be used in future robotized machines optimized for fruit harvesting. The embedded system is built around a state-of-the-art processor and a state-of-the-art miniaturized color camera. The selected processor requires very low power but operates at very high performance and is based on a constantly evolving ARM core proposal initially designed for the smart phone market.

The selected color camera also requires very little power and generates high quality images under bright natural illumination. The camera has an internal image matrix of 640 × 480 pixels and can be configured to generate the 320 × 240 pixel images required by the system in a normal and zoom mode. Additionally, the use of specific image formats, such as the RGB565, limits memory occupancy to 150 KB and also reduces the memory occupancy of the segmentation LUTs used to detect red peaches in the images.

The validation experiments performed with the proposed embedded system have shown that the tracking of a red peach can be updated 10 times per second and that the use of different LUTs optimized for the RGB565 image format generates very few noisy pixels in the segmented image (less than 11%). In both cases, the area of a red peach was estimated with an average error of less than 10% when the piece of fruit is not affected by occlusion. This update time is very important because the embedded system is designed to be included in the gripper tool of a robotic arm to control the approximation of the gripper to the fruit while the harvesting machine is in movement.

With this proposal, the gripper tool will be able to update its relative position with the target fruit 10 times per second. Finally, the experimental results obtained show ed that a LUT created from previously defined linear color models has slightly better segmentation results as it can better estimate the skin color relationships originated in the red peach by illumination changes.

Future work will center on evaluating high-resolution megapixel miniature color cameras to explore the definition of different image zooming operations while maintaining the QVGA size of the images acquired and the operational speed of the embedded system. Future work will also be focused on miniaturizing the embedded system in order to incorporate the system directly onto the gripping tool of a robotized arm designed for fruit harvesting.

Source: University of Lleida

Authors: Merce Teixido | Davinia Font | Tomas Palleja | Marcel Tresanchez | Miquel Nogues | Jordi Palacin