ABSTRACT

The development of an efficient and cost-effective solution to solve a complex problem (e.g., dynamic detection of toxic gases) is an important research issue in the industrial applications of the Internet of Things (IoT). An industrial intelligent ecosystem enables the collection of massive data from the various devices (e.g., sensor-embedded wireless devices) dynamically collaborating with humans. Effectively collaborative analytics based on the collected massive data from humans and devices is quite essential to improve the efficiency of industrial production/service.

In this study, we propose a collaborative sensing intelligence (CSI) framework, combining collaborative intelligence and industrial sensing intelligence. The proposed CSI facilitates the cooperativity of analytics with integrating massive spatio-temporal data from different sources and time points. To deploy the CSI for achieving intelligent and efficient industrial production/service, the key challenges and open issues are discussed, as well.

DEFINITIONS AND ADVANCES

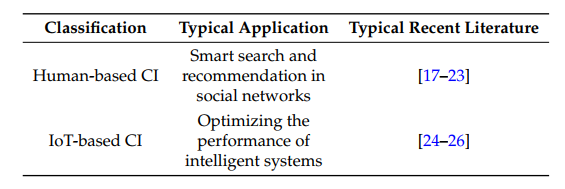

Table 1. Classification of the studies on collaborative intelligence (CI)

Based on the above advantages, CI has been widely studied. As an important existing platform for CI, HUB -CI (HUB with CI) is the next generation of collaboration-supported system developed at Purdue University. On this platform basis, Prabhu Devadasan et al. have designed the model CIMK that measures CI by the multi-objective optimization on the parameters of collaboration and suggest the optimal operating points for various clients, with greater flexibility. In Table 1, the relevant studies can be classified into two classes, human-based CI and IoT-based CI, depending on the difference of the participants.

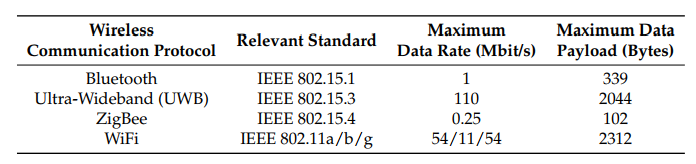

Table 2. Relevant protocols for industrial sensing intelligence (ISI)-based factory automation

An ISI-based factory automation system consists of various devices, e.g., sensors, controllers and heterogeneous machines, and these devices can be combined together through the communications between each other. The communication component is the most important part of factory automation. In Table 2, we list the communication protocols that can be used in ISI-based factory automation.

COLLABORATIVE SENSING INTELLIGENCE

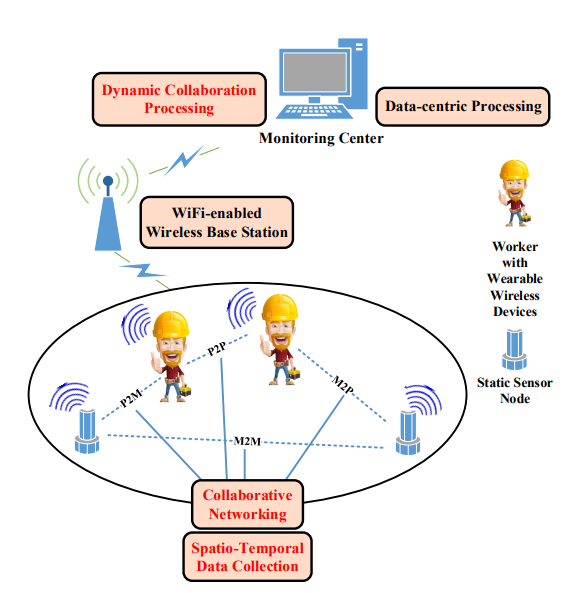

Figure 4. An application scenario of the CSI framework to improve the capability of detecting toxic gases in a large-scale petrochemical plant

This application consists of four components: sensor-embedded wearable wireless devices, static wireless sensor nodes, WiFi-enabled wireless base stations and a remote monitoring centre. The wearable wireless devices are worn by workers and collaborate with static wireless sensor nodes to sense the surrounding environment and collect spatio-temporal data.

The data are sent to the remote monitoring centre via WiFi-enabled wireless base stations. In the monitoring centre, based on the collected data, by data-centric dynamic collaboration, the collaborative networking among different wireless devices can be achieved. Such networking constructs a problem-solving network to detect the leakage of toxic gases. Moreover, on such a networking basis, the CSI can be achieved in this scenario.

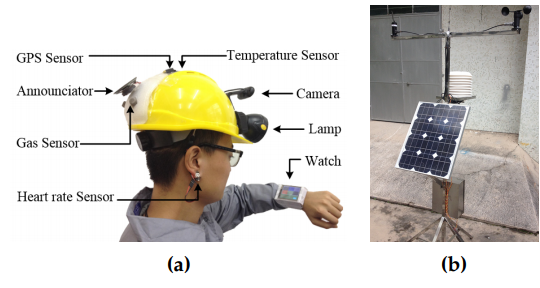

Figure 5. (a) Sensor-embedded wearable wireless devices: smart helmet and wrist watch; (b) static wireless sensor node

The smart helmet is sensor-embedded, and it works with the wrist watch to dynamically detect toxic gases. The static node is supported by solar energy and enables persistently measuring the concentration of gases in the air, e.g., CO,SO2 and CH4, and other environmental information,e.g., wind speed, humidity and temperature.

Figure 6. An example of networking two different data sources to improve the quality of service (a use case from La Poste)

Figure 6 provides an example: integrating two different data sources to improve the performance of services or solutions for mail delivery. This example is based on citizen sensing and machine sensing. Based on sensing and communication operations, sensors can share their data, which provides enhanced situational awareness that any system cannot offer alone.

Integrating the spatio-temporal data from citizen sensing with the data from machine sensing provides enhanced experience and situational awareness. Such integration forms more complete information than either forms of sensing can provide alone. Additionally, it enables collaborative networking among different wireless devices.

KEY CHALLENGES AND OPEN ISSUES

The CSI framework is used to face the growing demands of IoT and to achieve the intelligence of industrial production/service. The key challenges and open issues on deploying this framework to practical industrial applications are worthy to be investigated and discussed, considering the characteristics of industrial problems under the background of IoT and big data analytics.

Key Challenges

Data analytics: This is the bottleneck of the CSI framework, due to the lack of scalability for different datasets. Based on the characteristics of industrial problems, CSI analyses spatio temporal datasets. These datasets are collected from different industrial equipment and different time points, and they have different semantics, different formats, different sizes and different contexts.

Structuring data: Transforming unstructured data into a unified structured format for later analysis is a challenge for the CSI framework. As the basis of our intelligence framework, spatio-temporal data are not natively structured, e.g., daily running log data of different industrial equipment, and such unstructured data are typically text-heavy and contain important log information, such as dates, running parameters of equipment and values of these running parameters.

Functionality

Knowledge discovery: In the era of big data, for mining the potential of big data analytics, it is vitally important to discover knowledge with understanding the nature (e.g., correlations, contexts and semantics) of data. However, it is still an open challenge for the CSI framework, because knowledge discovery is a complex process under the dynamic environment of industrial production/service.

Effective and high-efficiency knowledge utilization: Along with the wide use of sensors and wireless devices in IIoT, data are being produced by humans and machines at an unprecedented rate. This leads many industrial departments to explore the possibility of innovating with the data that are captured to be used as a part of future information and communication technology (ICT) services. The major challenge is how to release and use the knowledge that is mined from the massive data of industrial department.

CONCLUSIONS

Facing the growing demands of industrial production/service on improving the safety, efficiency and eco-friendliness, as well as meeting the cost-effective objectives, based on the IIoT and the characteristics of industrial problems, we have proposed the CSI framework combining CI and ISI. This sensing- and collaboration-based intelligence framework has the potential to improve the performance of industrial systems by providing better awareness and control to dynamic industrial environments and correlated production/service processes, with analysing and integrating massive spatio-temporal data.

Moreover, because the spatio-temporal data are collected from things and humans, CSI can achieve improved automated decision making with ISI collaborating with the crowd wisdom of humans. In addition, the challenges and open issues for developing the CSI framework have been explored and discussed. The aim is to identify innovative research issues for industrial intelligence and to deploy the CSI framework to practical industrial applications.

Source: Liverpool John Moores University

Authors: Yuanfang Chen | Gyu Myoung Lee | Lei Shu | Noel Crespi

>> Latest IoT based Automation Projects for Engineering Students

>> 200+ IoT Led Projects for Final Year Students

>> IoT based Networking Projects for Engineering Students

>> More Wireless Embedded Projects for Engineering Students