ABSTRACT:

As one of the top ten core industries in China, Internet of things, has gradually changed our life, by influencing enterprise production, storage and transportation, express, supermarket shopping, etc.

By using Internet of things technology in the supply chain, enterprise can optimize the structure and process of supply chain management system, improve the information transmission speed and things matching accuracy, and improve the operation mode of supply chain.

The paper constructs a supply chain simulation system based on Internet of things. Firstly we analyze the process of the simulation system, and then introduce key techniques of simulation platform and main functions of the system. The work provides a basic platform for follow-up research of Internet of things, and a training system for students.

THE PROCESS DESIGN OF SIMULATION SYSTEM

Based on Internet of things and wireless network technology, the system realizes the trace of product life cycle and visual management. Driven by product sales, data sharing as the premise and supported by the Internet of things technology, the whole system is closed-loop supply chain system for simulation the entire operation including production, distribution centers, transportation enterprise and supermarket.

THE KEY TECHNIQUES IN THE SIMULATION SYSTEM

Production Environment Monitoring Subsystem:

Intelligent production environment monitoring system to use all kinds of sensors are gathering all the environmental information on production processes like temperature, humidity, pressure and degree of vibration information that will pushed to PC to store by ZigBee transmission network. ZigBee system include: embedded sensor nodes, RFID reader, PC, production line equipment, etc.

RFID Intelligence In-out Warehouse Management Subsystem:

RFID intelligence in-out warehouse management subsystem, its implementation intentions and logic as well as the traditional storage member manual input, is combined with the RFID tag, RFID reader, automatic control, computer, network and other advanced technology and equipment to complete goods in-out warehouse management. Purpose is to provide more convenient and flexible, more efficient, more powerful means of ware-house management.

Intelligent Transportation Monitoring Subsystem:

Vehicle location tracking system

Intelligent transportation monitoring system mainly involves in the GPS technology and GIS technology, the basic principle of GPS positioning is based on instantaneous position of the satellite high speed movement known as initial data, using the method of spatial distance resection to determine the test location.

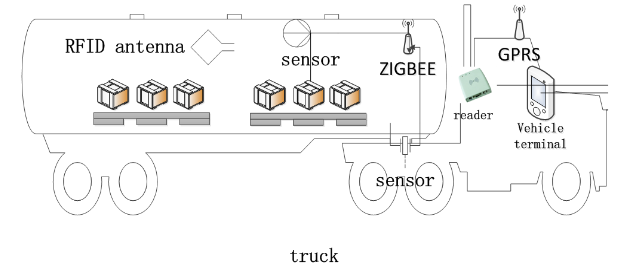

Vehicle Condition Monitoring Systems

Condition monitoring system for vehicles in road application of the wireless sensor technology. There are various types of sensors inside the car and tires such as temperature and humidity sensor, tire pressure sensor transfer vehicle state information to the car terminal through the ZigBee technology, using the GPRS technology transfer vehicle environmental information state data to the network server to realize real-time monitoring of the state of the vehicle. As shown in Figure 3.

Intelligent Goods Shelves Subsystem:

Smart shelves system can be achieved real-time monitoring goods information in shelves and update information of on or off shelves. Its design adds a reader antenna to each cargo grid of conventional shelf and every eight antenna connected to reader through an antenna adapter. According to the placing of the goods required, antenna be put on bottom and top of grids.

Smart Shopping Cart Subsystem:

The supermarket smart shopping carts act as assistants to assist the user to choose goods, its design is based on the existing shopping cart increase IPAD and RFID reader information interaction with server through wireless network.

THE FUNCTION DESIGN OF SIMULATION SYSTEM

Production Management:

Platform can simulate the whole process of production enterprises and make production smart management function through the application of IOT technology. Production management module include functions of product labeling, product processing and finished product checking; The production plan management module draw up the plan according to receive orders from system; Order management module includes viewing order information and order processing; Production management module of the system can manager product categories of system production.

Intelligent Distribution:

In simulated distribution link, distribution center according to the supermarket order generate stock out and distribution list, the former is given Warehouse and later is given transport sector After out of storage the system automatically updated inventory information; After the completion of out of storage, the goods is packing after passing sorting operations.

Intelligent Transportation:

Platform can simulate the whole process of transportation and realize intelligent transportation management functions through the application of IOT technology. In road link, the drivers of transportation get distribution list and complete the preparation activities to automatic complete the vehicle and the driver matching through the RFID technology, and start a series of executable program of vehicle like opening the GPS system automatically, show distribution tasks and route, etc.

Supermarket Foreground Sales:

Users, in the supermarket (shopping mall) using smart shopping cart for purchase, will place membership card that need to be registered and recharged early to swipe area, the system will read out the customer information At the same time it recommend discounts commodity to customers based on the user’s consumption records. When the user needs to choose and buy a commodity, it is able to find the location of the commodity according to the product category, intelligent touch screen can query the inventory and specific location information of commodity of system via WIFI network.

Supermarket Background Management:

- Supermarket background system mainly includes smart supermarket background management system and intelligent materials monitor system.

- Smart supermarket background management system, which can realize user management, commodity classification management, commodity in library management, sales management, after sales service, order management and system management functions.

- Intelligent materials monitor system, mainly including goods monitoring, shortage of monitoring materials parameter setting, system parameter setting, etc. Materials monitoring: intelligent terminal equipment that can show name, properties, quantity of the goods on each position of warehouse shelves.

CONCLUSION

This paper built a supply chain simulation platform system based on IOT technology, analyzed the application of key technology in the system, and designed smart shelves subsystem, smart shopping cart subsystem and so on.

The operation process is simulated according to the particularity of the supply chain enterprise The system can provide a full range of search service for customers through the WEB service, and realize the visualization management of the whole process of mobile commerce so the user can trace the whole process of goods for safety and achieve more efficient supply chain management.

Source: Beijing Wuzi University

Authors: Jie Zhu | Bin bin Fu

>> Latest RFID Based IoT Projects for Engineering Students

>> WiFi based IoT Projects for Engineering Students

>> IoT based Embedded Projects for Engineering Students with Free PDF Downloads

>> More Wireless Embedded Projects for Engineering Students