EXECUTIVE SUMMARY

Gilbert Chocolates has proposed to manufacture a machine to wrap chocolate bars. This machine is intended to replace two people wrapping the chocolate bars by hand, which is a time consuming method. This is especially apparent between October and January when the workers are working long hours in preparation for the Christmas rush of customers.

Currently wrapping a bar takes about a minute and Gilbert Chocolates wants this time reduced down to 20-30 seconds. The budget for this project is set at $1000, and is being funded by the company. This machine needs to fit in a cubic foot of space and weigh under 30 pounds for storage purposes. This device can be either purely mechanical with manual input, or it may use step motors and a controller.

This project pulls from our knowledge in kinematics, dynamics, 3D modeling, tolerance analysis, material selection, manufacturing techniques, and design of components. From doing this project we will learn how to apply all of these concepts together to solve real world problems. This project will encompass the design, manufacturing of a prototype, and optimization of the chocolate bar wrapping machine in hopes that the price of manufacturing chocolate bars can be reduced for Gilbert Chocolates.

The final presentation of this project will include a working prototype, a report, and a presentation. The project will be presented at the Engineering Senior Design Project day. The machine will be operated and displayed at this event.

CONCEPTUAL DESIGN

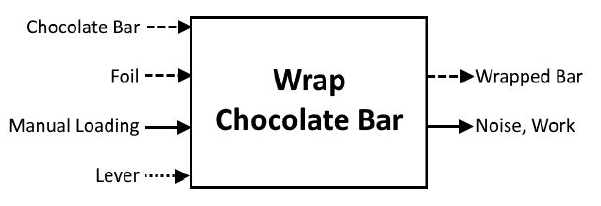

Figure 1: Overall Function Structure Diagram.

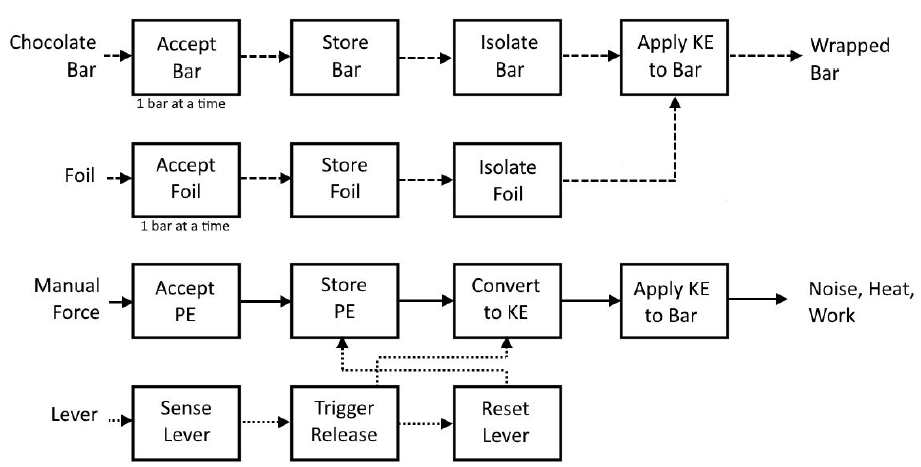

Figure 2: Detailed Function Structure Diagrams.

From these four function diagrams, we developed six distinct categories for our machine to satisfy. Manual input is how the operator will directly interact with the machine, putting the necessary energy to wrap the bar. Energy storage is how the motion of the manual input is stored in the machine until the wrapping occurs. Manual trigger is how the operator will release the stored energy, ultimately wrapping the bar. Loading method is how the bar will reach the wrapping zone. The wrapping method is how the foil will actually be wrapped around the chocolate bar. Then the unloading method will be how the finished bar will be removed from the machine.

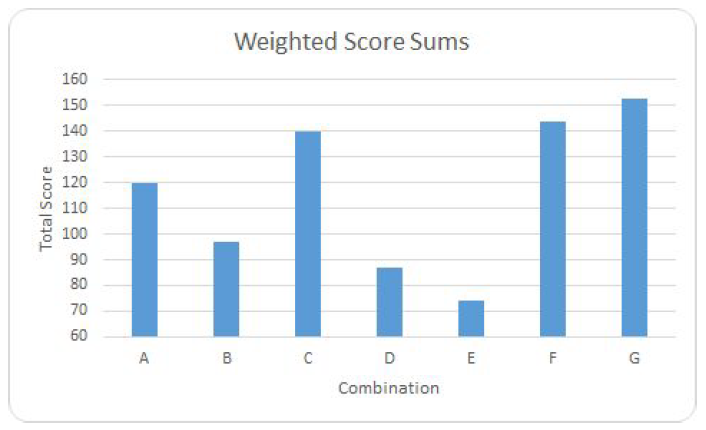

Figure 8: Weighted Score Sums.

In Figure 8, higher scores correlate to better performance, based upon the needs and corresponding ratings given above. From the weighted decision matrix, it was determined that option G would satisfy our needs the best, although options F and C are still worth consideration.

EMBODIMENT DESIGN

The following figures depict the general gear, pulley, and axle layout. The colored letters label the gears, the black letters label the shafts.

DETAIL DESIGN

Part Drawings

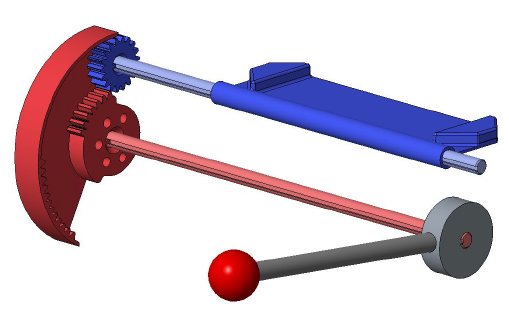

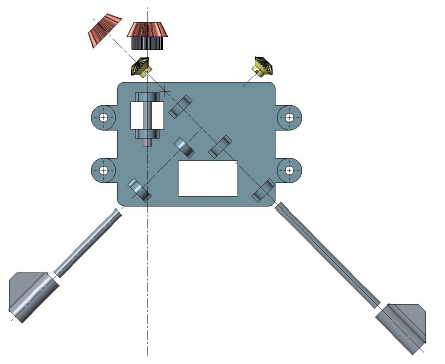

Figure 39: Planetary Gear Assembly.

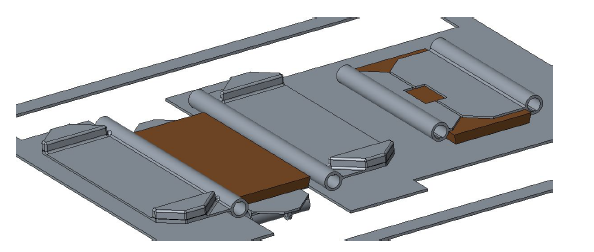

Figure 40: Table Flap Assembly.

Figure 41: Angular Bracket Exploded View.

DISCUSSION

With the design we selected, numerous gear calculations were needed to ensure correct operation of the machine. With our two levers, we had to accurately deliver the 180° of motion required to the flaps. For the long side of the foil flaps, we had to achieve 180° of motion both forward and back in one lever turn, for only one of the flaps. We designed it this way to prevent the two long foil flaps for colliding into each other. This is why the planetary gear was design. With the correct number of teeth and pitch on each gear in the set, the first flap folds in and comes back out before the second flap folds in.

CONCLUSION

This project was begun with the intent of designing a machine capable of decreasing the time needed for Gilbert Chocolate’s employees to wrap candy bars. By doing so, the workers could spend more time producing more chocolate to sell. Furthermore, the machine needed to be affordable for a small business, and needed to easily moveable for when it was needed.

The importance of all of these design criteria cannot be overstated. If the machine failed to reduce the time required to wrap the bars, the machine serves little benefit over wrapping by hand. Furthermore, if the machine costs well over $1000 dollars, the payback time may be undesirable. With further research and development, these machines could be improved and optimized for Gilbert Chocolates, but also for other small chocolate businesses. As the product is optimized, the cost of manufacturing can be reduced, making it more beneficial for more companies, and reducing their payback time.

We believe that this machine achieved its purpose. The price was below the stated price requirement, it reduces the time required to wrap the bars, and is contained within a cubic foot. We also believe that this product is marketable to other small chocolate businesses looking to reduce wrapping time without spending an exorbitant amount of money on a machine way beyond their product capabilities.

Source: The University of Akron

Authors: Austin M. Hoff | Daniel R. Trepke | Caleb B. Krichbuam