EXECUTIVE SUMMARY

Our team of engineers were given the task of coming up with a design project and designing the system, creating calculations, and brainstorming ideas. We set out to design a riding lawn mower lift. The purpose of this design was to assist in general maintenance like replacing blades, oil changes, etc.

To accomplish this task, our team started to brainstorm ideas and make sketches to look at all the options. We then did research and looked at different size lawn mowers and looked at the specifications. This helped our team to be able to design the size of platform needed to accommodate the size of the tractors. Then, calculations were performed to see the lifting power needed for the mower. Once all of the decisions and calculations were made, we designed the 3D model of our design.

As a result, our team of engineers have produced a lawn mower lift concept that is both functional and user friendly. This will help the customer have a more functional and more ergonomically friendly design to work on any repairs. We designed the lift to have the front end lift up significantly more than the back end so the user can change blades on a mower easier. Also the user could make the front and back end level to get under the vehicle to change oil or perform general maintenance with more room to work with under the vehicle. Once the concept was developed, we expanded our capabilities to other small motorized vehicles with four wheels, like four-wheelers, go-carts, or side-by-sides.

CONCEPTUAL DESIGN

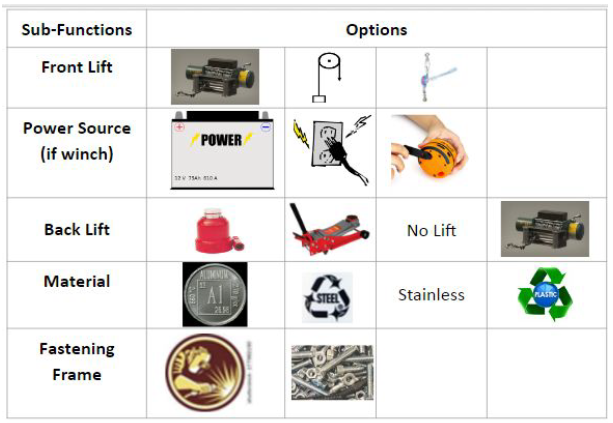

We created a morphological chart of the main components of the lawn mower lift. Our engineering team came up with an array of solutions for each component. We have a total of 288 total possible solutions for our Lawn mower lift from the table below.

Figure 1 – Morphological Chart.

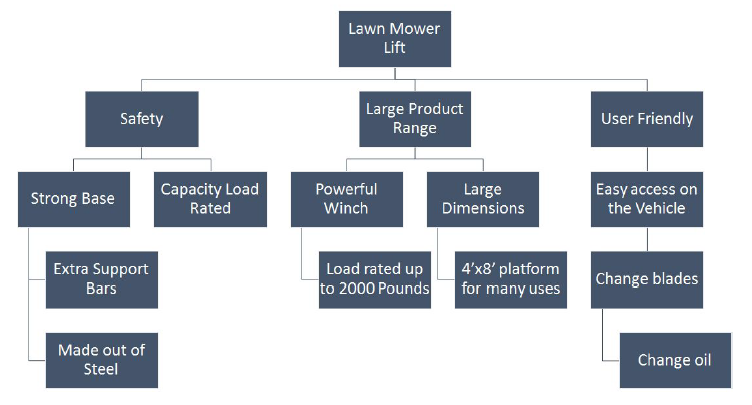

Figure 2 – Objective Tree.

Our team of engineers created an objective tree to look at all the advantages to this product and the benefits to the customer of this product.

EMBODIMENT DESIGN

There are 2 main functions of our lawn mower lift; lifting the front end of the mower and raising the whole back end. Our method to lift the front end will be the winch. The winch will be mounted on the front of the lift on a steel plate. This function will be powered by a 12 volt battery. The winch can support up to 2000 pounds. This will be a perfect device for tractors so it will be easy to lift the front end with a simple hook. The winch and battery are affordable, reliable, and durable for this type of use.

The other main function will be lifting the back end platform. We decided that we would use a low profile bottle jack. This will range from as low as 6” to 14.5” and can handle up to 4000 pounds. The jack for the lift is ideal because the jack is made of steel and it is a hydraulic jack. The winch will be bolted to the frame for support and the bottle jack will have a frame that will attach it to the whole system. The whole frame and all of the supporting pipes will be attached by welds.

DISCUSSION

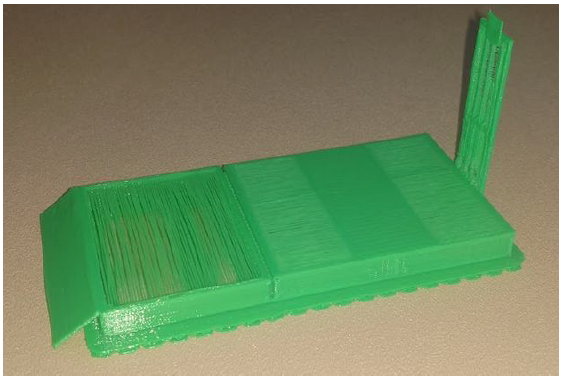

Figure 5 – Prototype (3D Printed Model).

For our ME Design Project, our team came up with an idea to manufacture a lawn mower lift. The purpose of this design was to assist in general maintenance like replacing blades, oil changes, etc. Other designs we saw only lifted the front by about a foot. One still had to lay on the ground to do any maintenance. Ours on the other hand puts the working area at about 2 and a half feet which is the perfect level if sitting on a garage stool. While working on this project, we were able to display our engineering skills that we have learned from the classroom.

CONCLUSION

Looking forward, we wanted to produce a full-size model but because of financial reasons we were limited to a prototype.For simplicity reasons, we chose to have our model 3D printed rather than fabricated out of steel. Down the road, if finances allow, we may actually produce one of these lifts for personal use (since the design work is already completed). After that, there is always a possibility it taking off! Below is a picture of our 3D printed model of our riding lawn mower lift.

Source: The University of Akron

Authors: Randall E. Schelcher