ABSTRACT

Background

Scholars tend to view global sourcing as a one-way street, whereby multinational manufacturers from developed countries purchase low-cost materials and products from developing countries. Undoubtedly, one of the purchasing bases for them is China because of its abundant resources and cheap labor. That is why China is aptly called the “Global Factory.” Conversely, few Chinese manufactures currently adopt a global sourcing strategy. However, the higher demand for technical quality and an increase in manufacturing cost is driving more Chinese manufacturers to adopt a global sourcing strategy in order to improve their competitive advantage. This would help them to optimize the use of global resources.

Purpose

The purpose of this master thesis is to analyze what problems and challenges Chinese manufacturing companies face in the implementation of a global sourcing strategy.

Research Method

Our study shall analyze the situation and problems encountered when Chinese manufacturers implement a global sourcing strategy. To achieve this deep understanding we need to perform a qualitative investigation of some Chinese manufacturers. Hence, we chose qualitative research as our methodology of this thesis.

Conclusion

Pursuing global sourcing is a process which takes a long time and involves many obstacles to be overcome. In this complicated situation, there is not a universal compass to pursue global sourcing. Inexperienced Chinese manufacturers have to deal with each problem in order to develop an advanced level of global sourcing and to face the challenges from logistics capabilities, selecting foreign sources, protectionism, regulations, and so on.

THEORETICAL FRAMEWORK

Figure2-1 From Domestic Purchasing, International Purchasing to Global Sourcing (own source).

“Purchasing‟ refers to a process by which an enterprise or organization attempts to acquire materials or products in order to attain their goals. In the process of purchasing the ownership and possession of goods will be transferred from the seller to the buyer. The activities of purchasing include enquiry, an order, tracking the order, supervising and accounting for an order, receiving goods, and making payment.

International purchasing relates to a commercial purchase transaction between a buyer and a supplier located in a different country. This type of purchase is typically more complex than a domestic purchase. Organizations must contend with longer material pipelines, increased rules and regulations, currency fluctuations, customs requirements, and a host of other variables such as language and time differences (e.g., Trent & Monczka, 2003; Monczka, Trent, & Petersen, 2008).

The four-stage model was further revised, resulting in a new five-stage model. Figure 2-2(Trent & Monczka, 2003) shows five levels of development of global sourcing and the developing trend of global sourcing strategy by the percentage of firms experiencing different levels of global sourcing.

RESEARCH METHOD

Scientific Approach

Based on the study of Arbnor & Bjerke(1997), there are three various scientific approaches used in the research of business: analytical, system and actors approach.

Analytical research means that the whole is the sum of its parts i.e. that it is possible to describe the whole as long as you have all information regarding the parts (Arbnor & Bjerke, 1997). When putting the distinct parts together, we can know the whole from one of them. According to this approach, a problem can be divided into smaller parts and these parts could be solved separately. Causality is always being considered as a significant point in the analytical researcher.

On the contrary, the system approach means that the whole is not the sum of its parts. In contrast with the analytical approach, the systematic researcher does not search for causality. The systematic researcher searches for forces that influence the system and the final relations between them (Clara & John, 2005).

RESULTS OF THE EMPIRICAL STUDY

Introduction of companies

In this section, we will present the results from our investigation. Before these results are given, we are must first introduce what kinds of Chinese companies accepted and responded to our questionnaire. In order to collect the information as comprehensively as possible, the companies we investigated are from six different industries representing a broad range of Chinese manufacturing: automotive, apparel, furniture, computer, electric equipment, and toys. In the results portion, we tagged them as Auto, Apparel, Furniture, Comp, Electric and Toy, respectively:

ANALYSIS OF THE PROBLEMS AND CHALLENGES OF GLOBAL SOURCING IN CHINESE MANUFACTURERS

State of Chinese Manufacturing Industry

The Chinese manufacturing industry has achieved a dramatic increase in the 30 years since the government implemented the policy of reformation and opening markets. There are two reasons driving the evolution of Chinese manufacture: One is huge internal demands from local markets, namely the demands from construction of basic infrastructure and higher demands to improve the living standard for Chinese people. Another one is the transfer of international manufacturing industry (Xu K. , 2005).

Due to the fact China is experiencing the middle stage of industrialization, the Chinese manufacturing industry plays a crucial role in the rapid growth of Chinese GDP. Currently China is the third largest economy in the world, after the USA and Japan.

Chinese manufacturers, including 17 sub-industries, can be classified into three main parts. The first part includes light industry, textile industry and commodity manufacture, which accounts for 30.24% of manufacturing in China (Xu K. , 2005). The second part is resources machining industry, including the processing of rock oil, petrochemicals, rubber, and nonmetal and so on, which holds one-third of the whole gross in the Chinese manufacturing industry.

CONCLUSION

According to our investigation of Chinese manufacturers the problems emanating from logistics do not annoy Chinese manufacturers very much. Three of the six manufacturers who responded said that logistics was not a problem at all and the other three reported that it was only a minor problem. We arrived at this conclusion after telephone interviews with several manufacturers. Basically, three reasons account for this:

First, most of the companies we investigated, such as the computer manufacturer and Haier, are large and experienced enterprises, having special logistics departments to deal with logistics problems, even in complicated global sourcing processes.

Second, some manufacturers such as the furniture manufacturer have only purchased some advanced equipments from abroad only two or three times so logistics issues are not an ongoing problem.

Third, the utilization of 3PL, or third-party logistics, can provide professional services to help them to overcome the challenges from logistics in global sourcing. And as our questionnaire found, five out of six of the Chinese companies surveyed use 3PL frequently.

When it comes to the long lead time and high-level of inventory, it is unavoidable in global sourcing. Chinese manufacturers are also experiencing these challenges to some extent. Four out of six reported that they had to increase inventory when purchasing from abroad, although not very often.

In addition, Chinese manufacturers that purchase materials from abroad are enjoying the relative lower price of international transportation because the fact export from China costs more than the import. Basically, the cargo ships returning to China are emptier than the ships departing from China, which leads to the cheaper transportation costs for importing goods from abroad because of the simple economics of supply and demand.

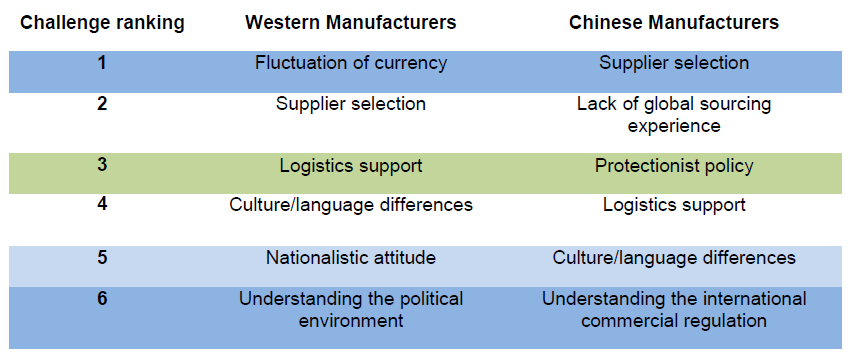

Table 6-1 The different challenges ranking between western manufacturers and Chinese manufacturers. (own source).

All in all, this table shows different ranked challenges between Western and Chinese manufacturers.

Source: Jönköping University

Authors: Chunnan Jiang | Yue Tian