THE NEED

Construction work zones are growing in number around the world. The natural aging of existing roadway infrastructure ensures that more and more maintenance and rehabilitation will be required. Work zones, by their very definition, create two major problems that must be addressed in some way: safety and mobility. In the United States, highway work zones are responsible for almost 25% of all non-recurring congestion and 10% of overall congestion.

Vehicle accidents are more common in work zones, and traffic congestion through work zones on urban arterials and freeways is often considered to be “unavoidable.” Fortunately, technology is providing new solutions to these problems at an accelerated rate. By combining the best of these new technologies, agencies can effectively reduce injury accidents and mitigate traffic congestion through construction work zones.

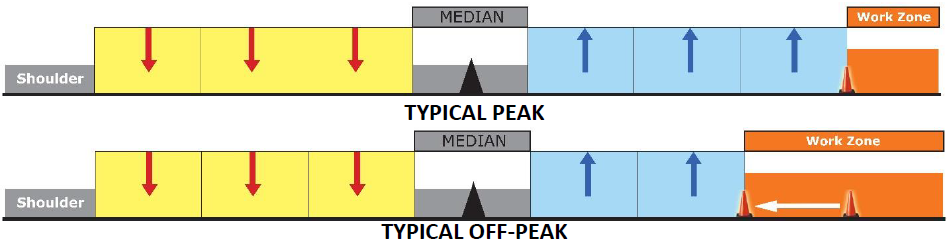

Figure 3 The work zone is efficient and traffic is not impacted, but encroachment accidents will still occur.

The third scenario is the most efficient use of the roadway. In this case, the maximum number of lanes is made available to motorists during peak traffic hours, and the road is reconfigured to increase the size of the work zone during off-peak traffic hours. This allows the contractor to create dedicated haul lanes, use larger equipment, accelerate the construction schedule, and create a safer working environment, while maximizing mobility and vehicle throughput for traffic.

THE TECHNOLOGY

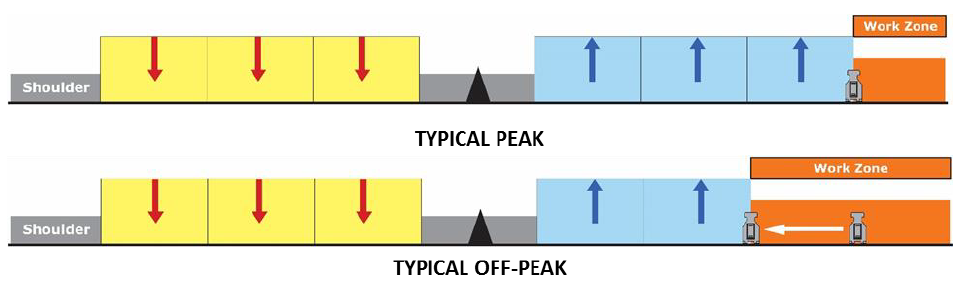

Figure 4 Moveable barrier reconfigures the roadway in real time with positive barrier protection.

Figure 5 Moveable barrier is used to expand the work zone and/or provide more lanes for peak traffic.

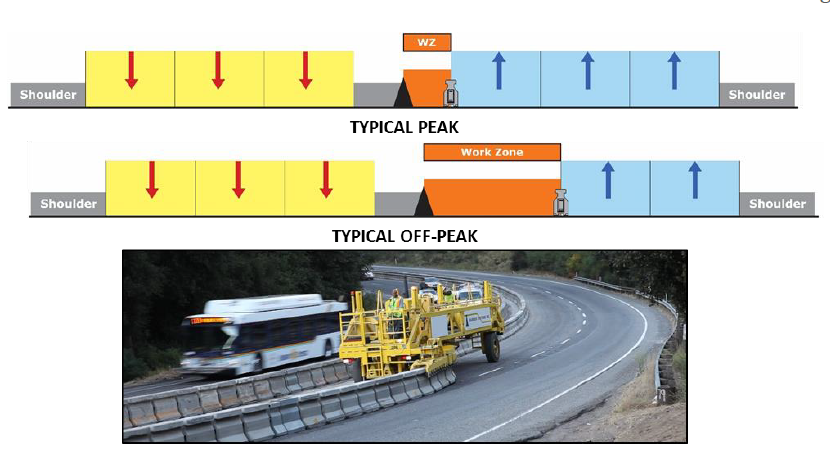

Moveable barrier is a two-part system. The first part consists of one-meter sections of highly reinforced concrete that are pinned together at each end to form a continuous barrier wall. The barriers have a T-top, which acts as a lifting surface for the transfer machine.

The second part of the system is a Barrier Transfer Machine (BTM), which lifts the barrier and passes it through a conveyor system, transferring the barrier from 8 to 24 feet (2.4 m to 7.3 m) in one pass at speeds up to 16km/h (1km can be reconfigured in four minutes). When necessary, the ends of the barrier are protected with a water-filled crash cushion that can articulate through the transfer machine for seamless operation.

Figure 6 The barrier can be stored at the edge of the road and moved out during off-peak traffic Periods to increase the size of the work zone in order to facilitate shoulder and median work.

For shoulder and median work, the barrier can be stored at the edge of the road and moved out during offpeak traffic periods to increase the size of the work zone. The barrier is returned to the stored position during peak traffic periods to give the maximum number of lanes to traffic. The barrier can be moved many times per day to meet the needs of both construction crews and motori

THE BENEFITS

Figure 8 Moveable barrier has major benefits on both highways and arterials.

It was determined that moveable barrier could keep two lanes open to traffic in the peak direction by using a total of only three lanes. This would give the contractor an extra lane to expand the work zone, keeping workers safe and accelerating construction. The barrier was moved multiple times daily to create a 1/2, 2/1 traffic pattern.

- Project was completed seven months early & saved one construction season

- Savings from early completion were estimated at US $1.3 to $1.4 million

- Reduced user delay costs

- US $1 million in accident cost reductions

- Total moveable barrier benefits estimated at US $2.4 million

- Moveable barrier benefit/cost ratio estimated between 4:1 and 10:1.

STATUS

The concept for the Road Zipper has been around for 30 years, but the technology is not necessarily well known in the industry. DOTs are quick to see the benefits in time and dollars saved as well as safety, but contractors tend to rely on techniques such as temporary asphalt and additional stages due to their familiarity with these better known methods.

BARRIERS

Moveable barrier is a tool best used where space is limited and the contractor and motorists can all benefit from additional space. If the construction work zone is already open and efficient with dedicated haul lanes and no impact on traffic, moveable barrier would not be an appropriate choice.

Moveable barrier saves contractors time and money when the work zone is confined and inefficient, and can benefit from being expanded one or more lanes as traffic permits. If an expanded work zone does not affect peak traffic flow when opposing traffic lanes have a static positive barrier between them, then using moveable barrier between opposing traffic lanes will not have any additional benefits.

Source: Purdue University

Authors: Purdue ECT Team